Pipes & Fittings

Besides copper there are many other options for your water tab installation. Let us help you choose the best option.

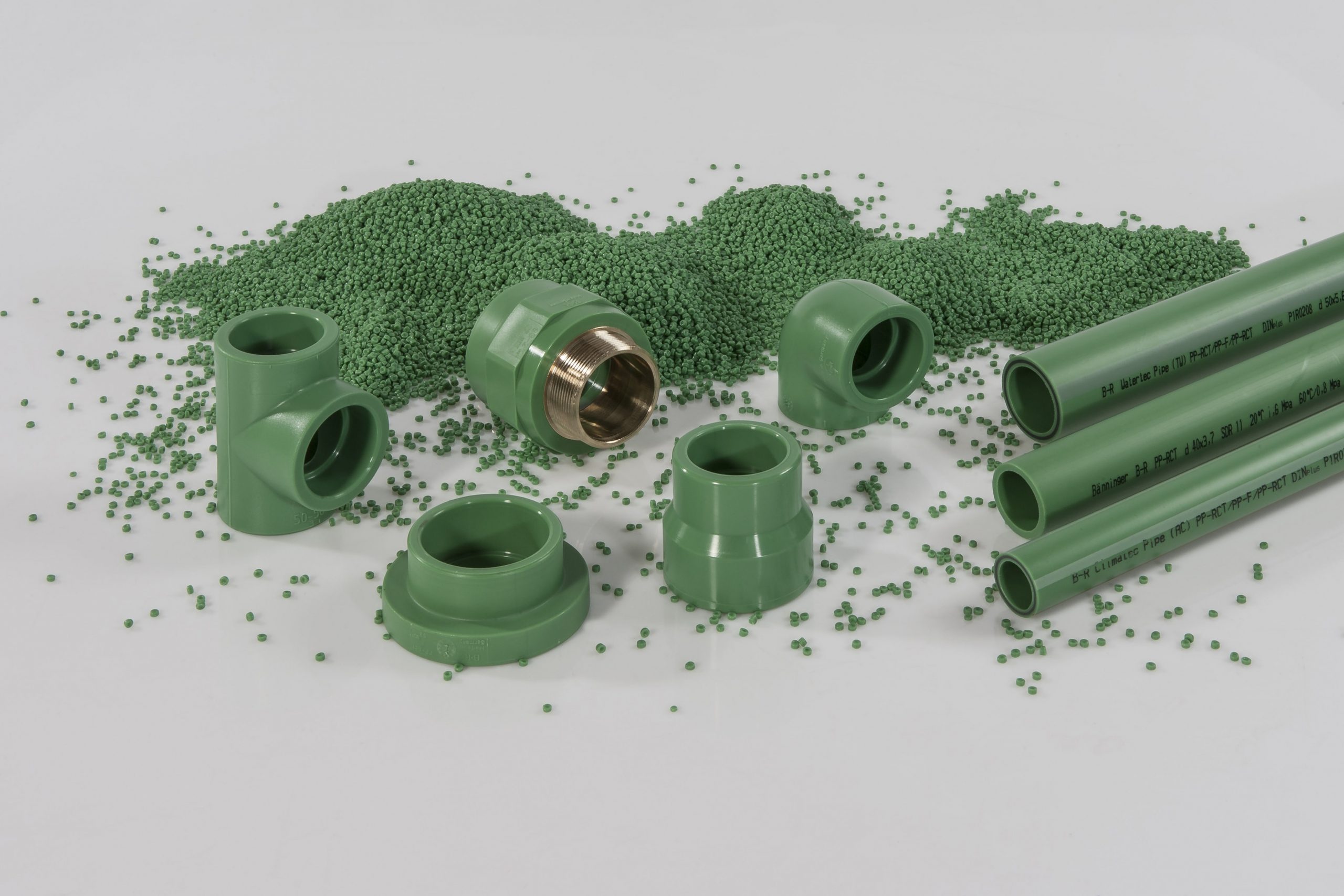

Beanninger PP-R

Pipes and Fittings made of PP-R for the environmental friendly supply of drinking water. Compared to PE, PP-R has higher rigidity, particularly in the upper temperature range. The high resistance to chemicals and good long-term properties compared to many other materials, even at high temperatures, are characteristic for PP-R.

How to attach a pipe to a fitting

The Socket Welding Machine is for sale and also for rent. The rent is Naf.100 per day with Naf.200 deposit. For the complete technical manual, download the PDF.

Multitubo System

Highest material quality: With an experience of more than 25 years in producing overlapped welded multi-layer pipes MULTITUBO systems is holding a pipe which safety-resource isone of the highest worldwide.

Highest material safety: Selected raw materials and a long experience in production guarantee the top quality of a technical perfected product. The pipe offers a high load capacity at tmax 95°C and pmax 10 bar (at 70°C according to the DVGW-regulations) for daily use.

Simple bendability: The standard diameters up to 25mm can be easily bent without any tools. The bending-springs provide exact roundings at narrow bending radii.

Advantages like metal-pipes:

- Absolutely oxygen tight because of the welded aluminium pipe.

- Form stable, no spring back forces.

- Low thermal length expansion.

Advantages like plastic pipes:

- No deposits because of the smooth inside wall.

- No corrosion because of the high chemical resistance.

- Low weight.

Pipe Cutter and Pipe Cutting Tool: To cut the requested pipe length right-angled the Pipe Cutter up to dim. 20 mm and the Pipe Cutting Tools up to dim. 75 mm are available.

Bevelling Tool: Ergonomically designed, the Bevelling Tools – Handle with Bevelling Inserts and Combined Bevelling Tool – allow an easy handling to make an adequate edge all over the pipes end.

Bending Spring: By using the Inside- or Outside-Bending Spring adequate radii for radiator-connections in corners can be achieved.

Pressing: Independent from an electrical power supply the pressing of the connections can be done by using the Battery Pressing Tools (for sale and for rent. The rent is Naf.100 per day with Naf.500 deposit). Alternative Dim. 16 mm up to 20 mm can be manually pressed by using the Manual Pressing Tool (for sale).

Welding machine: By using the Heat Element and the exchangeable Welding Tools a safe connection can be rapidly done.

Pipe Uncoiler and Straightener: With the Pipe Uncoiler an easier pipe laying is possible. For an exact adjustment of the pipe the Pipe Straightener can be mounted on the Pipe Uncoiler.